The eccentric wheel adjustment mechanism is the core component of the automatic chocolate pattern decorating machine. It not only determines the diversity and personalization of the decorative pattern, but also is the cornerstone of efficient production. By simply adjusting the position of the eccentric wheel, the producer can quickly change the distance between the decorative head and the chocolate surface, thereby achieving precise control of the size, density and shape of the decorative pattern. The design of this mechanism greatly simplifies the process of product changeover, reduces the downtime caused by changing molds or adjusting parameters, and significantly improves production efficiency.

More importantly, the eccentric wheel adjustment mechanism gives producers unprecedented flexibility. Whether it is classic retro fine stripes, modern and simple wide sawtooth, or even complex patterns customized according to specific festivals or brand themes, they can be easily achieved by adjusting the eccentric wheel. This flexibility not only meets the market's demand for personalized and differentiated products, but also provides producers with a broad creative space, making each chocolate product a unique work of art.

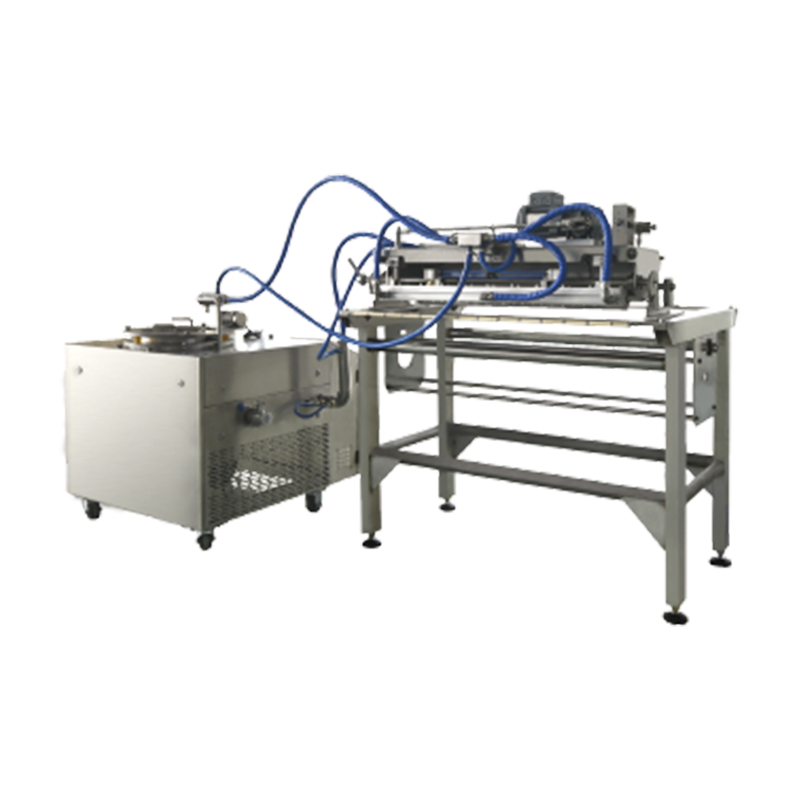

In addition to the innovative design of the eccentric wheel adjustment mechanism, the automatic chocolate pattern decorating machine also incorporates advanced automation and intelligent technologies to further improve production efficiency. The equipment usually uses high-precision sensors and intelligent control systems, which can monitor key parameters in the decoration process in real time, such as chocolate flow, temperature, decoration speed, etc., to ensure that each decoration can achieve the best effect. The intelligent system can also automatically adjust the working mode according to production needs, such as continuous operation mode in mass production, or intermittent operation mode in small-scale customization, so as to maximize production efficiency while ensuring product quality.

In addition, the automatic chocolate pattern decoration machine is also easy to maintain. The structure of the equipment is reasonably designed, and the key components are easy to disassemble and clean, which greatly reduces the maintenance cost and time. Suppliers usually provide comprehensive technical support and training services to ensure that producers can master the equipment operation and maintenance skills and further improve the overall efficiency of the production line.

In a rapidly changing market environment, the flexibility and response speed of the production line are the key to the competitiveness of enterprises. The eccentric wheel adjustment mechanism of the automatic chocolate pattern decoration machine, combined with automation and intelligent technology, enables the production line to quickly adapt to the production needs of different products and batches. Whether it is a quick response to urgent orders or the development and testing of new products, the equipment can complete the adjustment in a short time to ensure that the products are delivered on time and meet market demand.

This flexibility not only enhances the market competitiveness of enterprises, but also provides more business opportunities for producers. For example, during specific holidays or promotional events, manufacturers can quickly adjust decorative patterns and launch limited edition chocolate products that match the festive atmosphere to attract consumer attention and enhance brand image and sales performance.

中文简体

中文简体 English

English Français

Français عربى

عربى